What does earth leakage do to the machine, what would it look like on printers? How to test?

appreciate any and all info.

appreciate any and all info.

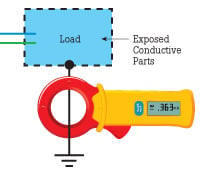

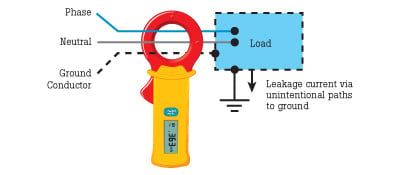

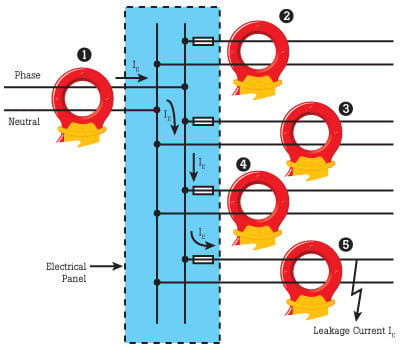

In any electrical installation, some current will flow through the protective ground conductor to ground. This is usually called leakage current. Leakage current most commonly flows in the insulation surrounding conductors and in the filters protecting electronic equipment around the home or office. So what's the problem? On circuits protected by GFCIs (Ground Fault Current Interrupters), leakage current can cause unnecessary and intermittent tripping. In extreme cases, it can cause a rise in voltage on accessible conductive parts.

In any electrical installation, some current will flow through the protective ground conductor to ground. This is usually called leakage current. Leakage current most commonly flows in the insulation surrounding conductors and in the filters protecting electronic equipment around the home or office. So what's the problem? On circuits protected by GFCIs (Ground Fault Current Interrupters), leakage current can cause unnecessary and intermittent tripping. In extreme cases, it can cause a rise in voltage on accessible conductive parts.

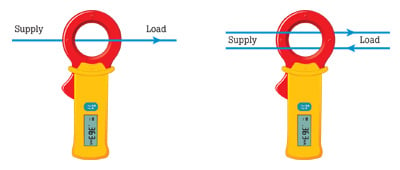

Measurement of leakage current to ground

Measurement of leakage current to ground

Comment