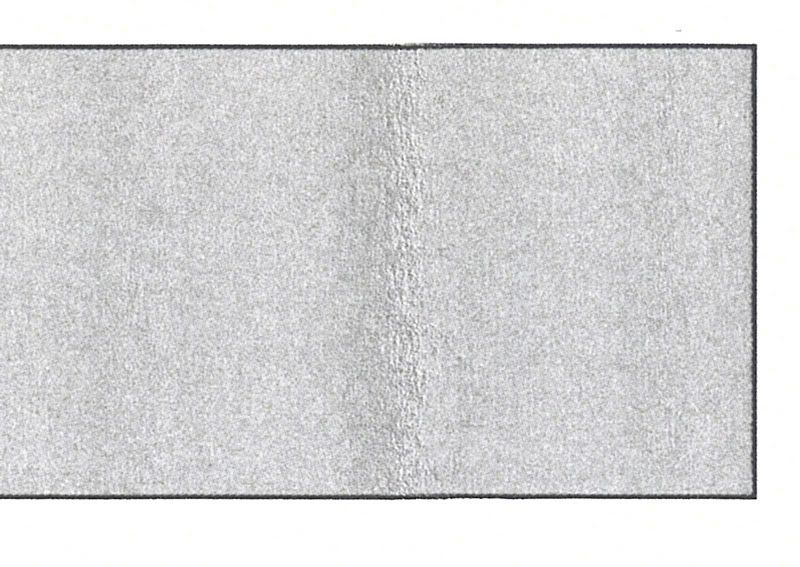

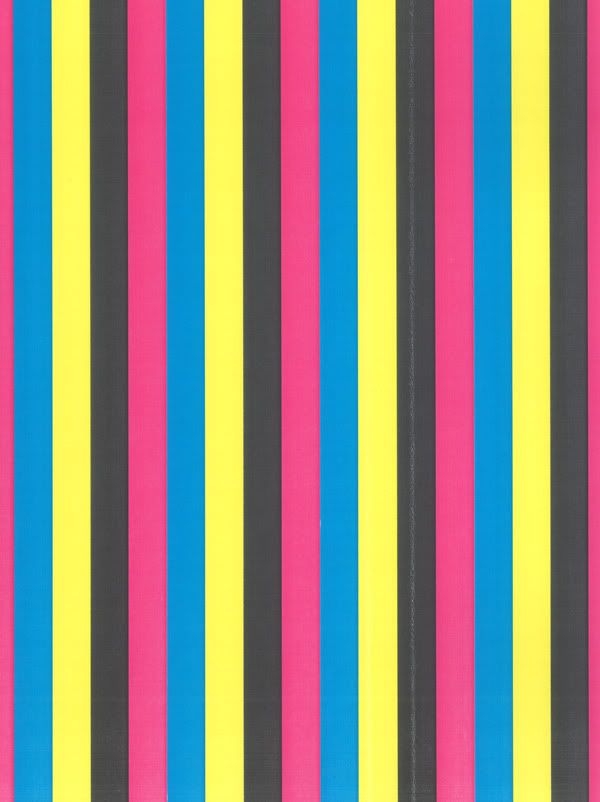

Our C3220 have strange vertical line, it affect all colors and is from top to bottom of the sheet, not always at the same position, it can move about 1 inch left or right, but it's always on the right side of the sheet and it don't show on every print (About once every 5 copy)

My first reflex was to check the ITB unit, I disassembled it and everything was perfect, not dirty at all, the drive roller was not dirty either, the Secondary transfer internal roller was a little bit more dirty but not enough to explain the problem.

I cleaned everything and the problem is still there.

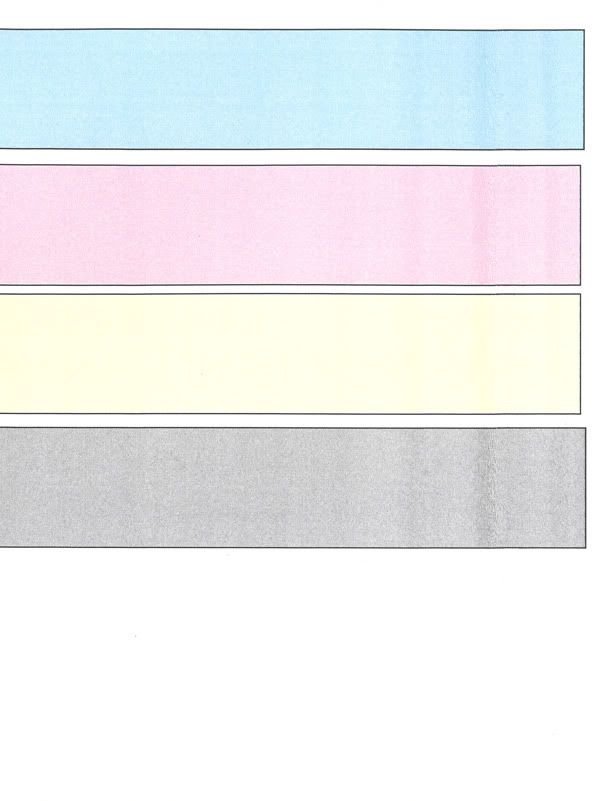

Here is pictures of the problem, it really look like a roller speed synchronization problem or something like that.

Thanks for the help.

My first reflex was to check the ITB unit, I disassembled it and everything was perfect, not dirty at all, the drive roller was not dirty either, the Secondary transfer internal roller was a little bit more dirty but not enough to explain the problem.

I cleaned everything and the problem is still there.

Here is pictures of the problem, it really look like a roller speed synchronization problem or something like that.

Thanks for the help.

Comment