Ok, if I could see this, ICP15 open, which tried to explain to Stirton.M was that if the PRCB is damaged, the service call code is always present, the only way to make it work again is to replace the PRCB, I think Stirton trying to explain this, how strange was that again had the problem.

in this case only two remaining possibilities: Damaged cables or connectors, TDS, developer abnormalities.

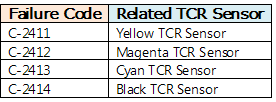

If you replace the TDS (TCR) by another unit, you'll notice immediately that the problem is not in the TDS, maybe acknowledgment C-2412.

Another reason, the Developing unit is empty, or with small amount of developer.

You should review the list of management to control, if the history of high service called low-density codes maybe earlier.

). The issue in this particular case has been resolved. As I said, replacing the harness on the process unit fixed the problem.

). The issue in this particular case has been resolved. As I said, replacing the harness on the process unit fixed the problem.

Comment